Pure Water Occasional Archive

Back Issues of the Occasional from June 2006 to present.

This is a pretty comprehensive listing of old Pure Water Occasional issues. Email issues going back to mid-2006 are listed in the table in reverse chronological order, beginning with the most recent. We haven’t counted them, but there are a bunch. New issues are added periodically to the top of the list.

The Occasional is the offspring of the original Pure Water Gazette which began as a mail-out paper newsletter in 1986. The paper Gazette, discontinued in 1997, morphed into an online publication which started emailing some of its content as the Occasional sometime in the early 2000s. The Gazette has existed since then as an online publication with “occasional” email issues.

Below the table, you will find duplicate listing of issues that are archived on the old Pure Water Occasional website. This list, which mainly covers 2009 to 2013, contains broad subject headings.

You can sign up to receive new Pure Water Occasional issues by using the box on the right upper corner of this page or from the home page of the Pure Water Products website.

Mid-2006 to present in reverse chronological order.

Newsletter Archives:

| Subject |

Date |

| Pure Water Occasional, December 31, 2024 |

Dec 31, 2024 |

| Pure Water Occasional, November 30, 2024 |

Nov 30, 2024 |

| Pure Water Occasional, October 2024 |

Oct 31, 2024 |

| Pure Water Occasional, September 2024 |

Sep 30, 2024 |

| Pure Water Occasional, August 2024 |

Aug 31, 2024 |

| Pure Water Occasional July 2024 |

Jul 31, 2024 |

| Pure Water Occasional, June 30, 2024 |

Jun 30, 2024 |

| Pure Water Occasional, May 30, 2024 |

May 30, 2024 |

| Pure Water Occasional, April 30, 2023 |

Apr 30, 2024 |

| Pure Water Occasional, March 31, 2024 |

Mar 31, 2024 |

| Pure Water Occasional Feb. 29, 2024 |

Feb 29, 2024 |

| Pure Water Occasional January 2024 |

Jan 31, 2024 |

| Pure Water Occasional, December 31, 2023 |

Dec 31, 2023 |

| Pure Water Occasional, November 30, 2023 |

Nov 30, 2023 |

| Pure Water Occasional, October 31, 2023 |

Oct 31, 2023 |

| Pure Water Occasional, Sept. 2023 |

Sep 30, 2023 |

| Pure Water Occasional, August 2023 |

Aug 31, 2023 |

| Pure Water Occasional, July 31, 2023 |

Jul 31, 2023 |

| Pure Water Occasional, June 30, 2023 |

Jun 30, 2023 |

| Pure Water Occasional, May 31, 2023 |

May 31, 2023 |

| Pure Water Occasional, April 30, 2023 |

Apr 30, 2023 |

| Pure Water Occasional, March 31, 2023 |

Mar 31, 2023 |

| Pure Water Occasional, February 27, 2023 |

Feb 27, 2023 |

| Pure Water Occasional, January 31, 2023 |

Jan 31, 2023 |

| Pure Water Occasional, July 27, 2022 |

Dec 31, 2022 |

| Pure Water Occasional, Nov. 27, 2022 |

Nov 27, 2022 |

| Pure Water Occasional, October 30, 2022 |

Oct 30, 2022 |

| Pure Water Occasional, August 28, 2022 |

Aug 28, 2022 |

| Pure Water Occasional, July 27, 2022 |

Jul 27, 2022 |

| Pure Water Occasional, June 29, 2022 |

Jun 29, 2022 |

| Pure Water Occasional, April 17, 2022 |

May 30, 2022 |

| Pure Water Occasional, April 17, 2022 |

Apr 17, 2022 |

| Pure Water Occasional, March 12, 2022 |

Mar 12, 2022 |

| Pure Water Occasional, December 27, 2021 |

Dec 27, 2021 |

| Pure Water Occasional, November 9, 2021 |

Nov 9, 2021 |

| Pure Water Occasional, August 18, 2021 |

Aug 18, 2021 |

| Pure Water Occasional, June 17, 2021 |

Jun 17, 2021 |

| Pure Water Occasional, April 19, 2021 |

Apr 19, 2021 |

| Pure Water Occasional, February 14, 2021 |

Feb 14, 2021 |

| Pure Water Occasional, December 31, 2020 |

Dec 31, 2020 |

| Pure Water Occasional, November 25, 2020 |

Nov 25, 2020 |

| Pure Water Occasional, October 7, 2020 |

Oct 7, 2020 |

| Pure Water Occasional, August 23, 2020 |

Aug 23, 2020 |

| Pure Water Occasional, July 3, 2020 |

Jul 3, 2020 |

| Pure Water Occasional, May 22, 2020 |

May 22, 2020 |

| Pure Water Occasional, March 25, 2020 |

Mar 25, 2020 |

| Pure Water Occasional, February 18, 2020 |

Feb 18, 2020 |

| Pure Water Occasional, January 24, 2020 |

Jan 24, 2020 |

| Pure Water Occasional, December 23, 2019 |

Dec 23, 2019 |

| Pure Water Occasional, December 12, 2019 |

Dec 12, 2019 |

| Pure Water Occasional, November 19, 2019 |

Nov 19, 2019 |

| Pure Water Occasional, October 19, 2019 |

Oct 19, 2019 |

| Pure Water Occasional, September 28, 2019 |

Sep 28, 2019 |

| Pure Water Occasional, August 27, 2019 |

Aug 27, 2019 |

| Pure Water Occasional, July 27, 2019 |

Jul 27, 2019 |

| Pure Water Occasional, July 6, 2019 |

Jul 6, 2019 |

| Pure Water Occasional, June 14, 2019 |

Jun 14, 2019 |

| Pure Water Occasional, May 28, 2019 |

May 28, 2019 |

| Pure Water Occasional, April 30, 2019 |

Apr 30, 2019 |

| Pure Water Occasional, April 2, 2019 |

Apr 2, 2019 |

| Pure Water Occasional, March 17, 2019 |

Mar 17, 2019 |

| Pure Water Occasional, February 16, 2019 |

Feb 16, 2019 |

| Pure Water Occasional, February 2, 2019 |

Feb 1, 2019 |

| Pure Water Occasional, January 16, 2019 |

Jan 16, 2019 |

| Pure Water Occasional, December 12, 2018 |

Dec 12, 2018 |

| Pure Water Occasional, November 13, 2018 |

Nov 13, 2018 |

| Pure Water Occasional, October 17, 2018 |

Oct 17, 2018 |

| Pure Water Occasional, September 25, 2018 |

Sep 25, 2018 |

| Pure Water Occasional, August 28, 2018 |

Aug 28, 2018 |

| Pure Water Occasional, August 7, 2018 |

Aug 7, 2018 |

| Pure Water Occasional, July 13, 2018 |

Jul 13, 2018 |

| Pure Water Occasional, June 25, 2018 |

Jun 25, 2018 |

| Pure Water Occasional, June 15, 2018 |

Jun 15, 2018 |

| Pure Water Occasional, May 18, 2018 |

May 18, 2018 |

| Pure Water Occasional, April 21, 2018 |

Apr 21, 2018 |

| Pure Water Occasional, March 25, 2018 |

Mar 25, 2018 |

| Pure Water Occasional, February 25, 2018 |

Feb 25, 2018 |

| Pure Water Occasional, February 3, 2018 |

Feb 3, 2018 |

| Pure Water Occasional, January 6, 2018 |

Jan 6, 2018 |

| Pure Water Occasional, December 19, 2017 |

Dec 19, 2017 |

| Pure Water Occasional, November 27, 2017 |

Nov 27, 2017 |

| Pure Water Occasional, November 11, 2017 |

Nov 11, 2017 |

| Pure Water Occasional, October 28, 2017 |

Oct 28, 2017 |

| Pure Water Occasional, October 2, 2017 |

Oct 2, 2017 |

| Pure Water Occasional, September 7, 2017 |

Sep 7, 2017 |

| Pure Water Occasional, August 16, 2017 |

Aug 16, 2017 |

| Pure Water Occasional, July 31, 2017 |

Jul 31, 2017 |

| Pure Water Occasional, July 7, 2017 |

Jul 7, 2017 |

| Pure Water Occasional, June 10, 2017 |

Jun 10, 2017 |

| Pure Water Occasional, May 20, 2017 |

May 20, 2017 |

| Pure Water Occasional, April 28, 2017 |

Apr 28, 2017 |

| Pure Water Occasional, April 14, 2017 |

Apr 14, 2017 |

| Pure Water Occasional, March 14, 2017. |

Mar 14, 2017 |

| Pure Water Occasional. February 14, 2017 |

Feb 14, 2017 |

| Pure Water Occasional, January 29, 2017 |

Jan 29, 2017 |

| Pure Water Occasional, January 2, 2017 |

Jan 2, 2017 |

| Pure Water Occasional, December 12, 2016 |

Dec 12, 2016 |

| Pure Water Occasional November 27, 2016 |

Nov 27, 2016 |

| Pure Water Occasinal, October 31, 2016 |

Oct 31, 2016 |

| Pure Water Occasional, September 30, 2016 |

Oct 3, 2016 |

| Pure Water Occasional, August 31, 2016 |

Aug 31, 2016 |

| Pure Water Occasional, July 31, 2016 |

Jul 31, 2016 |

| Pure Water Occasional. June 20, 2016 |

Jun 20, 2016 |

| Pure Water Occasional, May 31, 2016 |

May 31, 2016 |

| Pure Water Occasional, April 30, 2016 |

Apr 30, 2016 |

| Pure Water Occasional, March 28, 2016 |

Mar 30, 2016 |

| The Pure Water Occasional. February 23, 2016. |

Feb 23, 2016 |

| Pure Water Occasional. January 25, 2015 |

Jan 25, 2016 |

| Pure Water Occasional. December 21, 2015 |

Dec 22, 2015 |

| Pure Water Occasional. November 30, 2015 |

Nov 30, 2015 |

| Pure Water Occasional, Oct. 31, 2015 |

Nov 1, 2015 |

| Pure Water Occasional. October 6, 2015 |

Oct 6, 2015 |

| Pure Water Occasional, September 9, 2015 |

Sep 9, 2015 |

| Pure Water Occasional, August 24, 2015 |

Aug 24, 2015 |

| Pure Water Occasional. August 3, 2015 |

Aug 3, 2015 |

| Pure Water Occasional. July 15, 2015 |

Jul 15, 2015 |

| Pure Water Occasional. June 15, 2015 |

Jun 15, 2015 |

| Pure Water Occasional. May 31, 2015 |

May 31, 2015 |

| Pure Water Occasional. April 30. 2015 |

Apr 30, 2015 |

| Pure Water Occasional. March 19, 2015 |

Mar 19, 2015 |

| Pure Water Occasional. March 2, 2015 |

Mar 2, 2015 |

| Pure Water Occasional. February 23, 2015 |

Feb 23, 2015 |

| Pure Water Occasional. February 16,2015 |

Feb 16, 2015 |

| Pure Water Occasional. February 9, 2015 |

Feb 9, 2015 |

| Pure Water Occasional. February 2, 2015 |

Feb 2, 2015 |

| Pure Water Occasional. January 26, 2015 |

Jan 26, 2015 |

| Pure Water Occasional. January 19, 2015. |

Jan 19, 2015 |

| Pure Water Occasional. January 12, 2015 |

Jan 12, 2015 |

| Pure Water Occasional — January 5, 2014 |

Jan 5, 2015 |

| Pure Water Occasional. December 29, 2014 |

Dec 29, 2014 |

| Pure Water Gazette. December 22, 2014 |

Dec 22, 2014 |

| Pure Water Occasional. December 15, 2014 |

Dec 15, 2014 |

| Pure Water Occasional. December 8, 2014 |

Dec 8, 2014 |

| Pure Water Occasional. December 1, 2014 |

Dec 1, 2014 |

| Pure Water Occasional. November 24, 2014 |

Nov 24, 2014 |

| Pure Water Occasional. November 17, 2014 |

Nov 17, 2014 |

| Pure Water Occasional. November 10, 2014 |

Nov 10, 2014 |

| Pure Water Occasional. November 3, 2014 |

Nov 3, 2014 |

| Pure Water Occasional. October 27, 2014 |

Oct 27, 2014 |

| Pure Water Occasional. October 20, 2014 |

Oct 20, 2014 |

| Pure Water Occasional. October 13, 2014 |

Oct 13, 2014 |

| The Pure Water Occasional. October 6, 2014 |

Oct 6, 2014 |

| Pure Water Occasional, September 29, 2014 |

Sep 29, 2014 |

| Pure Water Occasional. September 22, 2014 |

Sep 22, 2014 |

| Pure Water Occasional. September 15, 2014 |

Sep 15, 2014 |

| Pure Water Occasional. September 8, 2014 |

Sep 8, 2014 |

| Pure Water Occasional. September 1, 2014 |

Sep 1, 2014 |

| Pure Water Occasional, August 25, 2014 |

Aug 25, 2014 |

| The Pure Water Occasional. August 18, 2014. |

Aug 18, 2014 |

| Pure Water Occasional. August 11, 2014 |

Aug 11, 2014 |

| Pure Water Occasional. August 4, 2014 |

Aug 4, 2014 |

| Pure Water Occasional. July 28, 2014 |

Jul 28, 2014 |

| Pure Water Occasional. July 21, 2014 |

Jul 21, 2014 |

| Pure Water Occasional. July 14, 2014 |

Jul 14, 2014 |

| Pure Water Occasional. July 7, 2014 |

Jul 7, 2014 |

| Pure Water Occasional. June 30, 2014 |

Jun 30, 2014 |

| Pure Water Occasional. June 23, 2014 |

Jun 23, 2014 |

| Pure Water Occasional. June 16, 2014. |

Jun 16, 2014 |

| Pure Water Occasional. June 9, 2014 |

Jun 9, 2014 |

| The Pure Water Occasional. June 2, 2014 |

Jun 2, 2014 |

| Pure Water Occasional. May 26, 2014 |

May 26, 2014 |

| Pure Water Occasional. May 19, 2014 |

May 19, 2014 |

| Pure Water Occasional. May 12, 2014 |

May 12, 2014 |

| Pure Water Occasional, May 5, 2014 |

May 5, 2014 |

| Pure Water Occasional. April 28, 2014 |

Apr 28, 2014 |

| Pure Water Occasional. April 21, 2014 |

Apr 21, 2014 |

| Pure Water Occasional. April 14, 2014 |

Apr 14, 2014 |

| Pure Water Occasional. April 7, 2014 |

Apr 7, 2014 |

| Pure Water Occasional. March 31, 2014 |

Mar 31, 2014 |

| The Pure Water Occasional, March 24, 2014 |

Mar 24, 2014 |

| Pure Water Occasional, March 17, 2014 |

Mar 17, 2014 |

| Pure Water Occasional. March 10, 2014 |

Mar 10, 2014 |

| The Pure Water Occasional, March 3, 2014 |

Mar 3, 2014 |

| Pure Water Occasional, February 24, 2014 |

Feb 25, 2014 |

| Pure Water Occasional, February 17, 2014 |

Feb 17, 2014 |

| Pure Water Occasional, February 10, 2014 |

Feb 10, 2014 |

| Pure Water Occasional, February 3, 2014 |

Feb 3, 2014 |

| Pure Water Occasional, January 27, 2014 |

Jan 27, 2014 |

| Pure Water Occasional, January 20, 2014 |

Jan 20, 2014 |

| Pure Water Occasional. January 13, 2014 |

Jan 13, 2014 |

| The Pure Water Occasional. January 6, 2014 |

Jan 6, 2014 |

| Pure Water Occasional. December 30, 2013 |

Dec 30, 2013 |

| Pure Water Occasional. December 23, 2013. |

Dec 23, 2013 |

| Pure Water Occasional, December 16, 2013 |

Dec 16, 2013 |

| Pure Water Occasional. December 9, 2013 |

Dec 9, 2013 |

| Pure Water Occasional. December 2, 2013 |

Dec 2, 2013 |

| Pure Water Occasional. November 25, 2013 |

Nov 25, 2013 |

| Pure Water Occasional, November 18, 1013 |

Nov 18, 2013 |

| Pure Water Occasional. November 11, 2013. |

Nov 11, 2013 |

| Pure Water Occasional. November 5, 2013. |

Nov 4, 2013 |

| Pure Water Occasional, October 28, 2013 |

Oct 28, 2013 |

| Pure Water Occasional, October 21, 2013 |

Oct 21, 2013 |

| Pure Water Occasional, October 14, 2013 |

Oct 14, 2013 |

| Pure Water Occasional. October 7, 2013 |

Oct 7, 2013 |

| Pure Water Occasional. September 30, 2013. |

Sep 30, 2013 |

| Pure Water Occasional, September 23, 2013 |

Sep 23, 2013 |

| Pure Water Occasional, September 16, 2013 |

Sep 16, 2013 |

| Pure Water Occasional, September 9, 2013 |

Sep 9, 2013 |

| Pure Water Occasional, September 2, 2013 |

Sep 2, 2013 |

| Pure Water Occasional, August 26, 2013 |

Aug 26, 2013 |

| Pure Water Occasional, July 19, 2013 |

Aug 19, 2013 |

| Pure Water Occasional, August 12, 2013 |

Aug 12, 2013 |

| Pure Water Occasional, August 5, 2013 |

Aug 5, 2013 |

| Pure Water Occasional. July 29, 2013 |

Jul 29, 2013 |

| Pure Water Occasional, July 22, 2013 |

Jul 22, 2013 |

| Pure Water Occasional, July 15, 2013 |

Jul 15, 2013 |

| Pure Water Occasional, July 8, 2013 |

Jul 8, 2013 |

| Pure Water Occasional, July 1, 2013 |

Jul 1, 2013 |

| Pure Water Occasional, June 24, 2014 |

Jun 24, 2013 |

| Pure Water Occasional, June 17, 2013 |

Jun 17, 2013 |

| Pure Water Occasional, June 10, 2013 |

Jun 10, 2013 |

| Pure Water Occasional, June 3, 2013 |

Jun 3, 2013 |

| Pure Water Occasional Memorial Day 2013 Issue |

May 27, 2013 |

| Pure Water Occasional, May 20, 2013 |

May 20, 2013 |

| Pure Water Occasional, May 13, 2013 |

May 13, 2013 |

| Pure Water Occasional, May 6, 2013 |

May 6, 2013 |

| Pure Water Occasional, April 29, 2013 |

Apr 29, 2013 |

| Pure Water Occasional Mid-April Issue |

Apr 15, 2013 |

| Pure Water Occasional March 2013 Issue |

Mar 31, 2013 |

| Pure Water Occasional Mid-March Issue |

Mar 15, 2013 |

| Pure Water Occasional February 2013 |

Feb 28, 2013 |

| Pure Water Occasional Mid-February Issue |

Feb 15, 2013 |

| Pure Water Occasional January 2013 Issue |

Jan 31, 2013 |

| Pure Water Occasional, January 2013 |

Jan 15, 2013 |

| Pure Water Occasional, December 2012 |

Dec 31, 2012 |

| Pure Water Occasional Mid-December Issue |

Dec 15, 2012 |

| Pure Water Occasional, November 2012 |

Nov 30, 2012 |

| Pure Water Occasional Mid-November Issue |

Nov 15, 2012 |

| Pure Water Occasional, October 2012 |

Oct 31, 2012 |

| Pure Water Occasional Mid-October Issue |

Oct 15, 2012 |

| Pure Water Occasional, September 2012 |

Sep 30, 2012 |

| Pure Water Occasional Mid-September Issue |

Sep 16, 2012 |

| Pure Water Occasional August 2012 |

Aug 31, 2012 |

| Pure Water Occasional Mid-August Issue |

Aug 15, 2012 |

| Pure Water Occasional Mid-July Issue |

Jul 15, 2012 |

| Pure Water Occasional June 2012 Issue |

Jun 30, 2012 |

| Pure Water Occasional-Mid-June Issue |

Jun 15, 2012 |

| Pure Water Occasional May Issue |

May 31, 2012 |

| Pure Water Occasional Mid-May Issue |

May 15, 2012 |

| Pure Water Occasional April Issue |

Apr 30, 2012 |

| Pure Water Occasional Mid-April Issue |

Apr 15, 2012 |

| Pure Water Occasional for March 2012 |

Mar 31, 2012 |

| Pure Water Occasional, Mid-March Issue |

Mar 16, 2012 |

| Pure Water Occasional, February 2012 |

Feb 29, 2012 |

| Pure Water Occasional–Mid-February Issue |

Feb 15, 2012 |

| Pure Water Occasional January 2012 |

Jan 31, 2012 |

| Pure Water Occasional – Mid-January Issue |

Jan 15, 2012 |

| Pure Water Occasional December Issue |

Dec 31, 2011 |

| Pure Water Occasional – Mid-December Issue |

Dec 15, 2011 |

| Pure Water Occasional November Issue |

Nov 30, 2011 |

| Pure Water Occasional, Mid-November Issue |

Nov 15, 2011 |

| Pure Water Occasional October Issue |

Oct 31, 2011 |

| Pure Water Occasional, Mid-October Issue |

Oct 15, 2011 |

| Pure Water Occasional September Issue |

Sep 30, 2011 |

| Pure Water Occasional. Mid-September Special Issue. |

Sep 15, 2011 |

| Pure Water Occasional, August 2011 |

Aug 31, 2011 |

| Pure Water Occasional Mid-August Issue |

Aug 15, 2011 |

| Pure Water Occasional for July 2011 |

Jul 31, 2011 |

| Pure Water Occsional Mid-July Issue |

Jul 15, 2011 |

| Pure Water Occasional for June 2011 |

Jun 30, 2011 |

| Pure Water Occasional Mid-June Issue |

Jun 15, 2011 |

| Pure Water Occasional for May 2011 |

May 31, 2011 |

| Pure Water Occasional Mid-May Issue |

May 15, 2011 |

| Pure Water Occasional for April, 2011 |

Apr 30, 2011 |

| Pure Water Occasional Mid-April Issue |

Apr 15, 2011 |

| Pure Water Occasional, March 2011 |

Mar 31, 2011 |

| Pure Water Occasional Mid-March Supplement |

Mar 15, 2011 |

| Pure Water Occasional – February 2011 |

Feb 28, 2011 |

| Pure Water Occasional Mid-Month Issue |

Feb 15, 2011 |

| Pure Water Occasional, January 2011 |

Jan 31, 2011 |

| Pure Water Occasional Mid-January Supplement |

Jan 15, 2011 |

| Pure Water Occasional–December 2010 |

Dec 31, 2010 |

| Pure Water Occasional Mid-Month Product Issue |

Dec 15, 2010 |

| Pure Water Occasional, November 2010 |

Nov 30, 2010 |

| Special Mid-Month Product Issue of the Pure Water Occasional |

Nov 15, 2010 |

| Pure Water Occasional for October 2010 |

Oct 31, 2010 |

| The Pure Water Occasional, September 2010 |

Sep 30, 2010 |

| Pure Water Occasional, August 2010 |

Aug 31, 2010 |

| The Pure Water Occasional for July 2010 |

Jul 31, 2010 |

| Pure Water Occasional June 2010 |

Jun 30, 2010 |

| Pure Water Occasional, May 2010 |

May 31, 2010 |

| Pure Water Occasional April 2010. |

Apr 30, 2010 |

| Pure Water Occasional. March 2010. |

Mar 31, 2010 |

| Pure Water Occasional, February 2010 |

Feb 28, 2010 |

| Pure Water Occasional, January 2010 Issue |

Jan 31, 2010 |

| Pure Water Occasional, December 2009 Issue |

Dec 31, 2009 |

| The Pure Water Occasional, Nov. 2009 |

Nov 30, 2009 |

| The Pure Water Occasional for October 2009 |

Nov 2, 2009 |

| The Pure Water Occasional |

Sep 16, 2009 |

| Making Water Green |

Jul 20, 2009 |

| Pure Water Occasional – Water & Water Articles |

Sep 11, 2008 |

| Water Softeners and “Water Softeners” |

Apr 24, 2008 |

| The Pure Water Occasional — Issue 03 |

Sep 13, 2006 |

| The Pure Water Occasional — Issue 02 |

Jun 23, 2006 |

Below is a list of partially indexed back Occasionals that may also be of interest. These are archived on the Pure Water Occasional website:

Special Product-Specific Issues, 2010 to 2013

November 15, 2010. Undersink Water Filters.

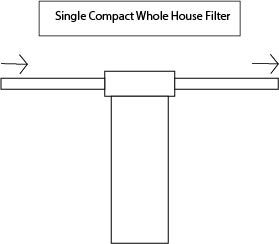

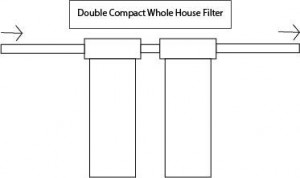

December 15, 2010. Cartridge-Style Whole House Filters.

January 15, 2011. Multi-Pure Solid Carbon Block Filters.

February 15, 2011. Water Treatment with Aeration.

March 15, 2011. Pure Water Annie’s Concise Guide to Pumps.

April 15, 2011. Garden Hose Filters.

May 15, 2011. Water Filters for Emergencies.

June 15, 2011. Backwashing Water Filters.

July 15, 2011. Countertop Reverse Osmosis.

August 15, 2011. Whole House Reverse Osmosis.

September 15, 2011. Sediment Filters.

October 15, 2011. Tank-Style City Water Filters.

November 15, 2011. The Amazing Permeate Pump.

December 15, 2011. Template Assisted Crystallization (TAC).

January 15, 2012. Electro-Adhesion Filtration Technology: NanoCeram Filters.

February 15, 2012. Information About Information: How To Find Things on Our Websites.

March 15, 2012. Water Filter Cartridges. Featuring Our Recent Cartridge Page Revision.

April 15, 2012. Undersink Installation in Tight Places. Low Water Backwashing Filter.

May 15, 2012. Chloramines: Myth and Reality.

June 15, 2012. Whole House RO. San Angelo Water Treatment Dilemma.

July 15, 2012. Water Testing. Sand Trap.

August 15, 2012. Our New Water Test Page. Taking Care of A Water Well.

September 15, 2012. Ultrafiltration. Birthday of the EPA and Model 77.

October 15, 2012. Installing Undersink Filters and Reverse Osmosis Units.

November 15, 2012. Water Softeners and TAC units.

December 15, 2012. Twin Tank Water Softeners.

January 15, 2013. Standard-Sized Filter Cartridges.

February 15, 2013. Chemical Feed Pumps.

March 15, 2013. Countertop Reverse Osmosis.

General Issues, 2009 to 2013

September 2009. “Meshes and Microns: The Measurements of Water Treatment,” by Gene Franks. “Numerical water facts from B. Bee Sharper.”

October 2009. “Providing Water for Emergencies.” by Gene Franks. “Humming is Good for You,” by Hardly Waite.

November 2009. “How Much Water Should You Drink?” by Dr. Mauro Di Pascuale. “Numerical Facts about Animal Manure,” by B. Bee Sharper.

December 2009. “The New York Times Great Water Article,” by Hardly Waite. “Numerical Facts,” by B Bea Sharper.

January 2010. “What Carbon Does and What It Doesn’t,” by Gene Franks. “Numerical Facts,” by Bee B. Sharper. “Acidic Water.”

February 2010. “Fluoridation: The Good, the Bad, and the Ugly, Part I,” by C. F. “Chubb” Michaud.

March 2010. “Fluoridation: The Good, the Bad, and the Ugly, Part II,” by C. F. “Chubb” Michaud.

April 2010. NSF/ANSI. What Is It All About? by Gene Franks. Dr. Douglas on bath pharmaceuticals. B. B. Sharper. Radium.

May 2010. “The Ceiling is Up and the Floor is Down: The Alamo Engineering Handbook,” by Gene Franks. Steve Maxwell on “Why Water Should Cost More.” Iron.

June 2010. “All About Water Softeners,” Occasional Staff Article. “Gulf Oil Spill: A Hole in the World,” by Naomi Klein (Guardian). B. Bee Sharper, “On Prescription Drugs.” Hardness.

July 2010. “Raising the pH of Acidic Waters,” by Pure Water Annie. “Arsenic,” with a long cut from National Geographic News, New Products from Pure Water Products.

August 2010. “Winterize Your Lawn,” Model 77’s 21’s Birthday, Pure Water Annie on Servicing Model 77, MTBE.

September 2010. “Getting a Perspective on Water Use,” by Gene Franks. The Permeate Pump and How to Add a Permeate Pump to Your RO Unit. “Nickel.” B. B. Sharper on Groundwater Usage.

October 2010. “Air and Carbon,” by Gene Franks. Pure Water Annie on Airgap Faucet Installation. New EPA rule on dental mercury. “Chloride.” The Dead Sea. B. Bea Sharper on Billions.

November 2010. “How to Fix Leaks in Quick Connect Fittings,” by Pure Water Annie. “A Simmering Water War,” by Jim Hightower, “Is Your Faucet Making you Sick?” by Doug Linney, B. Bea Sharper on Water, “Radium and Uranium,” and Lead (contaminant of the month).

December 2010. “Probable carcinogen hexavalent chromium found in drinking water in 31 U. S. Cities,” by Lyndsey Layton. “Most of the time no one is watching most of the water for most of the contaminants, “by Hardly Waite. “How to remove Hexvalent Chromium,” and “How Static Mixers Work,” by Pure Water Annie.

January 2011. How Much Sodium Does a Softener Add to Water?, Water Treatment for Rainwater, Fluoride Allowable in City Water Lowered, UnTruth in Advertising, Pure Water Annie’s Whole House Filter Sizing Chart.

February 2011. More about Hexavalent Chromium, Ten Things You Should Know About Water, “What Carbon Does, What Carbon Doesn’t,” by Gene Franks, The Ups and Downs of Filter Cartridges (Which End Goes Up), by Pure Water Annie. B. Bea Sharper on Dams and other issues.

March 2011. Hardly Waite on National Water Security Rankings, Pure Water Annie on Finding Parts for Your Water Filter, and Introducing the Emily Reverse Osmosis Unit.

April 2011. Rain Barrels, Plastics, Introducing The Eliminator, A New Website Address. “In Praise of Tap Water.”

May 2011. UV 101 by Gene Franks, Rain Gardens, Water Content of Trees, Fiberglass Mineral Tanks.

June 2011. Sizing Water Softeners by Pure Water Annie, Meshes and Microns by Gene Franks, Swimming Pool Leaks, Saving A Cell Phone from Water.

July 2011. Sizing Water Softeners Part 2, by Pure Water Annie. Dr. Mercola on Nitrosamines, Choramine, and Shampoo Ingredients. B. B. Sharper.

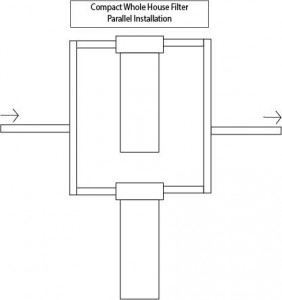

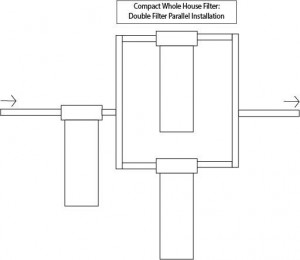

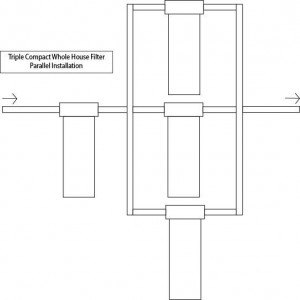

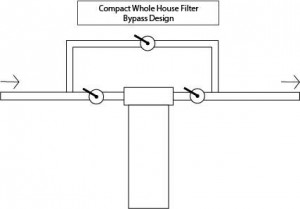

August 2011. The Best Water for Coffee and Tea. Multiple Filter Designs. Tiger Tom Explains How UV Works.

September 2011. The Power and Water Nexus. Pure Water Annie explains “The Peroxide Number.”

October 2011, Pure Water Annie’s Glossary of Water Treatment Abbreviations, Chloramines and Fish, The EPA, Water and Coal.

November 2011. Pure Water Annie on Pipe Threads. Gene Franks and Hardly Waite on Christmas Gifts. The Origins of Fluoride.

December 2011. Pure Water Annie on Well Pumps. Top Water News Stories of the Year.

January 2012, Pure Water Annie on Chlorine. Arsenic. Texas Drought. Texas Water.

February 2012. Pure Water Annie on Benzene. Lake Vostok. Banning Bottled Water.

March 2012. Pure Water Annie on Copepods. B. Bea Sharper on plastic bags. Fluoride in Food.

April 2012. Pure Water Annie on Booster Pumps. B. Bea Sharper on dog manure. USA Today on Dog Excrement. New Easiest Ever Filter. Arsenic.

May 2012. Pure Water Annie on Treating Water with Sodis and Salt, Hardly Waite on “fracking” and water treatment profits, B. B. Sharper on Animal Manure.

June 2012. Pure Water Annie on In/Out Filters. New “Sand Trap.”

July 2012. Pure Water Annie Explains How Undersink Reverse Osmosis Works. The Economy RO Unit.

August 2012. Chlorine, Cholesterol, and Chickens.

September 2012. Reverse Osmosis and Refrigerators. The New Contaminant Index. Meat and Water Consumption. B. Bea Sharper.

October 2012. Bypass Valves, Watts UV, New Green Filters, Decaffeination.

November 2012. Septic Tanks, Whole House Filters, Calcium Scaling, How Softeners Work.

December 2012. Mercury in Tuna, Rainwater Runoff (Ocean Pollution), How To Sanitize An RO Tank, Winter Swimming, B. Sharper.

January 2013. Green Water Management. Pure Water Annie on Microbe Control. Camp Lejeune’s Shameful Water Scandal.

February 2013. Hardness, Pharmaceuticals and Fish, Pure Water Annie on “Pressure, Flow Rate, and Delta P.”

March 2013. Alum, Sinkholes, pH, Multi-Pure.

![tapwater[3]](http://www.purewatergazette.net/blog/wp-content/uploads/2012/05/tapwater3-260x300.gif)